TESTING FACILITIES

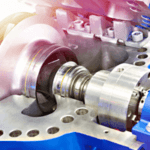

We are having testing facilities for Hydraulic Testing & Pneumatic Testing. All the Pumps & valves are 100% strictly tested at the required pressure as per the international standards and necessary documents are also being filed & also forwarded to client if needed.

Over the years, we have grown into one of the world's leading pumps & valves manufacturer. Today, the Megatech brand has a solid reputation for outstanding quality in India and around the world.Megatech Engineers is ISO 9001 Registered Company

Hydraulic test Facility

Hydro-pneumatic Testing Up to 50,000 PSI or as per your Requirement.

Pneumatic Test Facility

- Booster pump (intensifier): To test pneumatic pressure of Pumps & valves up to 10,000 PSI or as per your requirement.

- Pneumatic testing Machine: To test any Pumps & valves up to 2250 PSI or as per your requirement.

- Air Compressor : To test any fitting or Pumps & valves pneumatically up to 10 kg pressure or as per your requirement.

Valves will be subjected to 1.5 times of working pressure. Leaking will be tested by keeping the valves both in open and closed condition. The pressure will be released and Pumps & valves will be closed by bare hand without applying excess torque through hand tools, Hydraulic pressure shall be applied from one end there will be no seat leakage observed for a minimum period of 10 minutes. API 598, “Pumps & valves Inspection and Test”

The most widely used test specification in the world today. The document covers all types of valves in sizes through NPS 24. It also includes leakage rates and testing criteria for metal-seated and resilient-seated Pumps & valves.