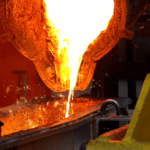

FOUNDRY

Megatech has professional expertise in supplying

castings for pumps conforming to all

international specifications as

(ASTM/BS/DIN/IS)

Megatech has experience of many pump types, pressure ratings, materials and specifications given by the customers.

T

he

Company’s customers include leading pump

manufacturers. The Company has experience of

producing pumps up to 2700 KGS in the black,

proof and finished machine condition.

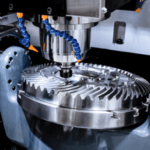

T

he

Company has achieved excellence in manufacturing

pressure tight castings with total soundness,

close dimensional tolerance, extraordinary

surface finish etc.

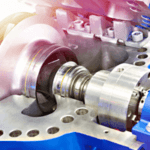

P

ump

castings in sophisticated materials such as

duplex stainless steels and nickel based alloys

or specialized applications include pumps like

boiler feed pumps, power station pumps,

centrifugal pumps, screw pump, positive

displacement pump, vertical pump, submersible

pump, high pressure double volute pump, high

speed pump, split casing pump, multi stage pump,

sewage pump, handling pump (open and S type

impellers), pulp handling pump, heavy chemicals

(mud type) pump, sea water handling pumps, ash

slurry handling pump, raw acid (with slurry)

handling pump, rotary pump, gear pump, oil pump,

twin lobe pump, piston pump, and many other

positive displacement and metering and dosing

pumps.

P

ump

castings in various metallurgical processes such

as WCB, CF8, CF8M, CF3M, alloy 20 (CN7M), CA15,

CA6NM, CD4MCu, S.G. Ni resist, high chrome steel

(28% Cr). Abrasion resistant cast irons like

high chrome cast iron and Ni hard (type1,2,4

& M). Nickel and nickel-based alloys like

Hastelloy B, C, 276 etc. We manufacture casting

as per ASTM, IS, BS, DIN and other international

specifications.

W

hen

you deal with Megatech , you can rest assured of

a unique understanding of your requirements,

specifications, pump design and testing,

engineering standards, reliability, assured

delivery within specific time frame, consistent

quality and competitive prices.